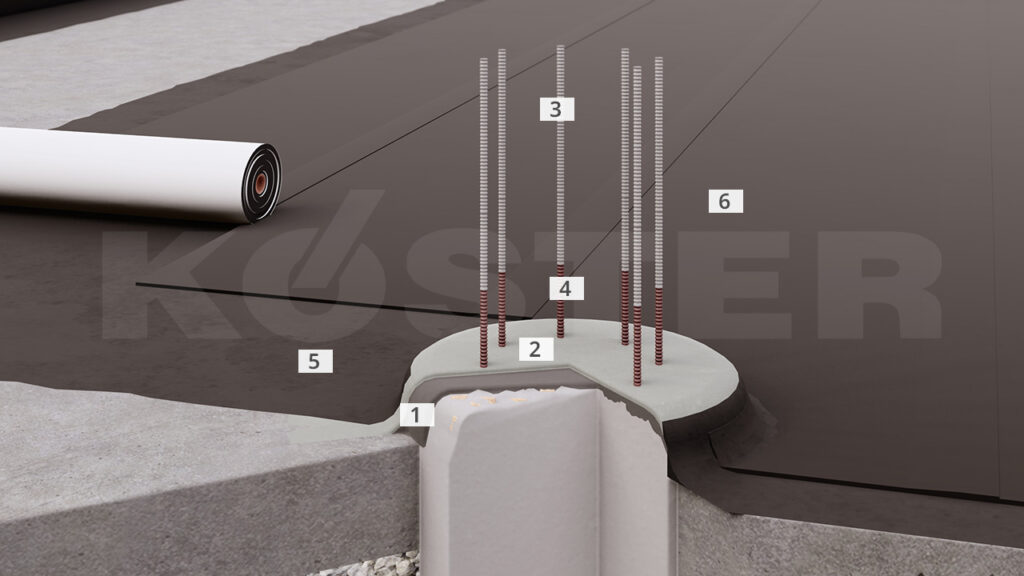

Damage in existing buildings is often caused by leaking pile foundations. Water can enter the building through the construction joints or make its way along the reinforcement steel. The waterproofing of pile heads has to withstand heavy loads from the whole building and needs to be easily connected to the area waterproofing.

At first, all non-load bearing materials and separating substances have to be removed from the surface of the pile head. After that, the surface has to be levelled and reprofiled with KÖSTER Repair Mortar or KÖSTER Repair Mortar R4. This reprofiling must also include the installation of a fillet adjacent to the pile head. KÖSTER NB 1 Grey is used to waterproof the pile head.

Mineral corrosion protection for the steel reinforcement bars is carried out with a first layer of the polymer modified special slurry KÖSTER Z 1 and a second layer of KÖSTER Z 2. KÖSTER Z 2 is red pigmented and allows a visual control of the application.

The waterproofing on top of the blinding layer is made with KÖSTER KSK SY 15. KÖSTER KBE Liquid Film is applied as primer on the entire surface as well as on all overlaps around the pile head. Protect the waterproofing layer from mechanical damage when continuing with the application.

Always adhere to the specifications in the respective Technical Guidelines.

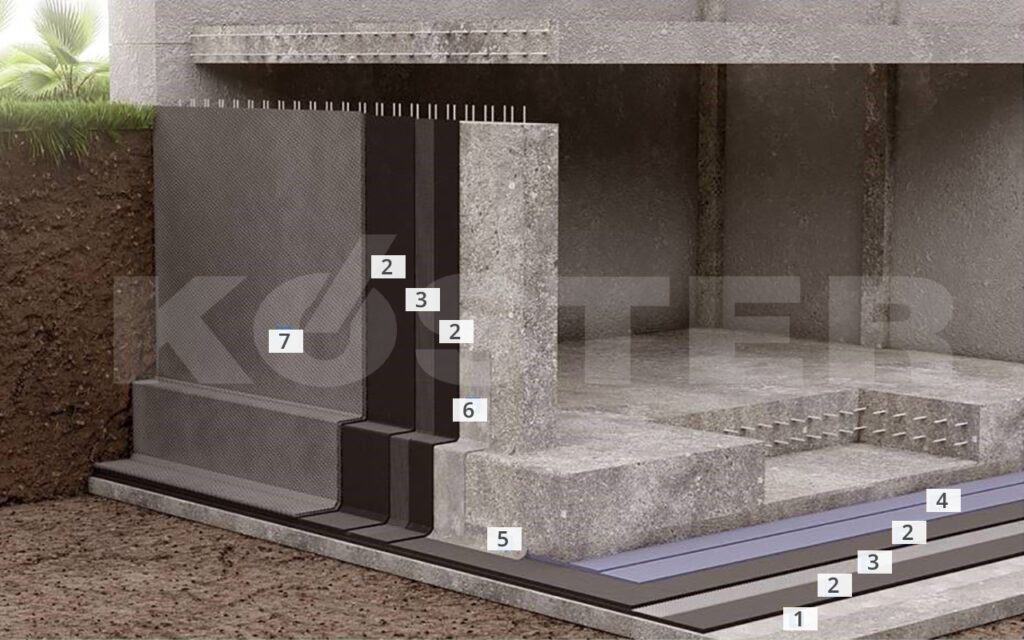

Damage in existing buildings is often caused by leaking pile foundations. Water can enter the building through the construction joints or make its way along the reinforcement steel. The waterproofing of pile heads has to withstand heavy loads from the whole building and needs to be easily connected to the area waterproofing.

At first, all non-load bearing materials and separating substances have to be removed from the surface of the pile head. After that, the surface has to be levelled and reprofiled with KÖSTER Repair Mortar or KÖSTER Repair Mortar R4. This reprofiling must also include the installation of a fillet adjacent to the pile head. KÖSTER NB 1 Grey is used to waterproof the pile head.

Mineral corrosion protection for the steel reinforcement bars is carried out with a first layer of the polymer modified special slurry KÖSTER Z 1 and a second layer of KÖSTER Z 2. KÖSTER Z 2 is red pigmented and allows a visual control of the application.

The waterproofing on top of the blinding layer is made with KÖSTER Deuxan 2C. Embed KÖSTER Glass Fiber Mesh into the fresh first layer. Before pouring the concrete for the floor slab, a gliding layer consisting of two layers of customary PE-Foil is applied between the waterproofing and the concrete. Protect the waterproofing layer from mechanical damage when continuing with the application.

Always adhere to the specifications in the respective Technical Guidelines.

A complete waterproofing system in new construction includes waterproofing the floor slab. Compared to the application on top of the concrete slab, the installation of the waterproofing layer underneath the foundation plate keeps the foundation dry and the concrete provides a better thermal insulation. KÖSTER provides a wide range of different solutions for completing the waterproofing under the foundation plates with total security.

If the choice is for a liquid application solution, it is necessary to first apply the primer KÖSTER Polysil TG 500 to lock any existing salts in the substrate and provide a better bond between the waterproofing and the substrate. For the liquid option, the choice can be the use of the PMBC system KÖSTER Deuxan 2C (applied in two layers with KÖSTER Glass Fiber Mesh reinforcement) or the novelty hybrid coating KÖSTER NB 4000 that allows the works to carry on even at extremely low temperatures.

For the pre-fabricated membranes, KÖSTER offers the 1.5 mm self-adhesive rubber-bitumen laminated membranes with 2 different top layers (HDPE or Aluminium Foil) called KÖSTER KSK SY 15 and KÖSTER KSK ALU 15. These types of membranes are cold applied, and are extremely easy and fast application, creating an immediate waterproofing effect.

Still in the pre-fabricated membranes, KÖSTER also offers the extremely resistant ECB (ethylene copolymer bitumen) membranes, that are mechanically fastened and/or loose-laid. The overlaps on these membranes are welded using hot air devices, guaranteeing a complete and secure waterproofing seal.

Always adhere to the specifications in the respective Technical Guidelines.

Exterior basement waterproofing from inside the building? In the case of renovation, it is not always possible to expose the exterior walls through excavation. For example, where the area to be excavated is built upon, traffic concerns impede the excavation, or the economic cost of excavation is deemed too high. You would first think of an internal (negative side) basement waterproofing, but in some cases, such as in historical buildings or buildings with special architectural requirements, this may not be desirable.

In these cases, a curtain injection with KÖSTER Injection Gel G4 is possible: The resin is injected through the wall from the inside to the outside. Water present behind the wall does not represent a challenge for the KÖSTER injection gels since they do not react with it, but instead it is bound in its matrix, resulting in a waterproof elastic solid body.

The injection is carried out with the special two-component pump, KÖSTER Acrylic Gel Pump, and through special KÖSTER injection packers.

Taking advantage of the extremely low viscosity of the gel, injection into difficult soil conditions like fine sand, silt and some clays is possible.

Always adhere to the specifications in the respective Technical Guidelines.

KÖSTER Thermoplastic Membranes are applicable for a wide variety of substrates and fields of application. As foundation waterproofing, they excel by their speed of application, durability, instant waterproofing effect, and can be backfilled immediately.

KÖSTER ECB Membranes consist of a mix of thermoplastic ethylene copolymer and a special bitumen, produced in Germany with the highest quality compounds and standards. KÖSTER ECB Membranes conform to DIN EN 13967:2012 and are rated as Type T moisture barriers. They provide high elongation and are highly tear resistant so that even large cracks are bridged securely.

KÖSTER ECB Membranes are free of pvc as well as plasticizers and are age and root resistant. As they can withstand high mechanical influences and stresses, they are the perfect protection for underground structures.

To ensure a watertight installation and long service life, the KÖSTER ECB membrane seams are welded homogeneously with hot air, using a special welding seam dedicated machine. A signal top layer shows any mechanical damage that can be repaired quickly and easily.

Before backfilling the waterproofing is protected from mechanical damage and settling with KÖSTER SD Protection and Drainage Sheet.

Always adhere to the specifications in the respective Technical Guidelines

Fast, clean, and easy: Exterior basement waterproofing with KÖSTER KSK cold applied, self adhesive waterproofing membranes. No drying time, instantly watertight, with a tight control of consumption. Apply a primer coat of KÖSTER KBE Liquid Film on clean, solid substrates. Pipe penetrations are sealed using flanges cut to size from KÖSTER KSK Membranes. In areas especially in danger of water creeping behind the waterproofing such as wall-floor junctions, a substrate preparation with KÖSTER NB 1 Grey mixed with KÖSTER NB 1 Flex is applied. To avoid stresses in the elastic waterproofing, rounded fillets made of KÖSTER Repair Mortar Plus are installed in interior corners.

The actual area waterproofing is generally done with KÖSTER KSK SY 15. It is applied crease free to the substrate. The membranes are overlapped 10 cm. Details, corners and connections are made according to the directions on the packaging and according to the Technical Guidelines, and these areas are covered with KÖSTER KBE Liquid Film. On vertical areas the top edge is mechanically fastened and these fasteners are also coated with KÖSTER KBE Liquid Film.

Before backfilling the waterproofing is protected from mechanical damage and settling with KÖSTER SD Protection and Drainage Sheet.

Always adhere to the specifications in the respective Technical Guidelines.

Mineral sealing slurries are especially robust waterproofing systems with extremely good adhesion to mineral surfaces. They are not affected by moist surfaces and become an integral part of the building structure on which they were applied. Mineral sealing slurries are paste-like and are applied seamlessly to the building element being waterproofed. They are easy and safe to apply and can be installed as rigid or crack bridging systems.

On clean, solid, stable, gypsum free mineral substrates KÖSTER Polysil TG 500 is applied as a primer. This immobilizes salts present in the substrate and the substrate is solidified.

Pipe penetrations are waterproofed using KÖSTER KB-Flex 200 and sealed with KÖSTER KB-Fix 5. Alternatively, these areas are to be attached to the waterproofing using proper sleeves or flanges.

The actual area waterproofing is achieved using KÖSTER NB 4000 in two layers. The installation of KÖSTER Glass Fiber Mesh is recommended between the KÖSTER NB 4000 layers to achieve an especially reinforced waterproofing layer. In areas especially in danger of water creeping behind the waterproofing such as wall-floor junctions, a substrate preparation with KÖSTER NB 1 Grey mixed with KÖSTER NB 1 Flex is applied. To avoid stresses in the elastic waterproofing, rounded fillets made of KÖSTER Repair Mortar Plus are installed in interior corners.

Before backfilling, the waterproofing is protected from mechanical damages and settling with KÖSTER SD Protection and Drainage Sheet.

Always adhere to the specifications in the respective Technical Guidelines.

The use of bituminous products belongs to the standard solutions for the positive side waterproofing of basements. The systems are applied in a paste-like form and are therefore seamless. They are easy and safe to use and have crack bridging properties. On clean, solid, stable, gypsum free mineral substrates KÖSTER Polysil TG 500 is applied as a primer. This immobilizes salts present in the substrate and the substrate is solidified. When preparing to waterproof on top of old bituminous coatings KÖSTER Bitumen Primer is used.

Pipe and cable penetrations are sealed with the permanently plastic putty KÖSTER KB-Flex 200 and protected by a layer of KÖSTER KB-Fix 5. Alternatively, these areas can be connected with a fillet of the respective thick film sealant or fitted with flanges.

To protect against water creeping behind the lower waterproofing connections, KÖSTER NB 1 Grey mixed with KÖSTER NB 1 Flex is applied first. To prevent stresses in the waterproofing, rounded fillets are installed in the wall / floor junctions.

The actual area waterproofing is achieved using KÖSTER Deuxan 2C in two layers applied by trowel or spray equipment. For greater ease of manual application use KÖSTER Bikuthan 1C or 2C. The inclusion of KÖSTER Glass Fiber Mesh is recommended in all thick film sealants and all applications. This allows for a better control of the coating thickness and safely absorbs movement in the building.

Before backfilling, the positive side waterproofing is to be protected from mechanical damages and settling with KÖSTER SD Protection and Drainage Sheet.

Always adhere to the specifications in the respective Technical Guidelines.

All Rights Reserved by Talrak Construction Pvt. Ltd.

Designed & Developed by Contentributor.