The method for waterproofing tunnels and reinstate its proper surface condition with KÖSTER products is based on a combination of negative side waterproofing and surface restoration systems.

Flowing water is stopped by injecting the water reactive elastic PU-injection resin KÖSTER 2 IN 1. Small leakages which are being penetrated by water as well as water droplet formations can be sealed with KÖSTER KD 2 Blitz Powder. To waterproof the entire surface from the negative side KÖSTER NB 1 Grey is applied to the prepared substrate. This is followed by a layer of the polymer modified levelling mortar KÖSTER C-Coat to create a uniform appearance. Finally, the system can be covered with a finishing touch of KÖSTER Acrylic Paint.

Always adhere to the specifications in the respective Technical Guidelines. Also observe the local guidelines and standards.

Several waterproofing systems can be applied to the negative pressure inner side. KÖSTER KD 2 Blitz Powder and KÖSTER Waterstop can be used to stop small leaks. Joints can be repaired with KÖSTER Repair Mortar or KÖSTER WP Mortar, and KÖSTER NB 1 Grey is to be applied on surfaces as negative side waterproofing.

A very difficult situation: The basement waterproofing has to be done from the inside but the water is actively entering the building. Often the only solution is the KÖSTER KD-System.

KÖSTER KD 2 Blitz Powder is applied directly by hand to the active leakage. The powder reacts within a few seconds and forms a waterproof mortar. When the active leakages are stopped, the waterproofing layer of KÖSTER KD 1 Base, KÖSTER KD 2 Blitz Powder and KÖSTER KD 3 Sealer can be applied.

The material is applied to substrates that have to be sound and solid as well as free of bond inhibiting agents. Older plaster coats have to be removed; the joints raked out and all loose particles removed. Generally, the substrate is primed by prewetting. Repairs and the installation of the fillet at the wall-floor junction are done with KÖSTER Repair Mortar Plus.

KÖSTER KD 1 Base is applied as the waterproofing layer and is brushed onto the substrate. KÖSTER KD 2 Blitz Powder is rubbed onto the still wet surface, immediately creating a dry waterproofed layer. To harden and to strengthen this layer, the third part of the system, KÖSTER KD 3 Sealer, is applied. To waterproof the basement completely, another two layers of KÖSTER KD 1 Base are applied over the first. Pipe penetrations are waterproofed with KÖSTER KB-Flex 200 sealing paste and plugged with KÖSTER KB-Fix 5.

In the case of damage to basement walls caused by moisture, generally a KÖSTER Restoration Plaster should be applied. KÖSTER Restoration Plasters are specially designed for the restoration of masonry with high salt and moisture contents. KÖSTER Restoration Plasters help to dry out the wall and absorb remaining salts. They don’t contain lime or gypsum, are open to water vapor diffusion and create a healthy and comfortable room climate.

Before the application of the main plaster coat, a plaster key made from KÖSTER Restoration Plaster Key or the chosen KÖSTER Restoration Plaster mixed with KÖSTER SB-Bonding Emulsion is applied to provide a larger surface area and ensure an optimal bond to the substrate.

KÖSTER Restoration Plasters are available in different varieties (grey, white, fast and light). KÖSTER Restoration Plaster White is often used in older buildings without subsequent painting. KÖSTER Fine Plaster creates a very smooth surface and can be applied when desired to meet architectural goals. KÖSTER Restoration Plasters can only be painted over with breathable (open to vapor diffusion) paints such as KÖSTER Silicone Paint White or KÖSTER MF1.

Always adhere to the specifications in the respective Technical Guidelines.

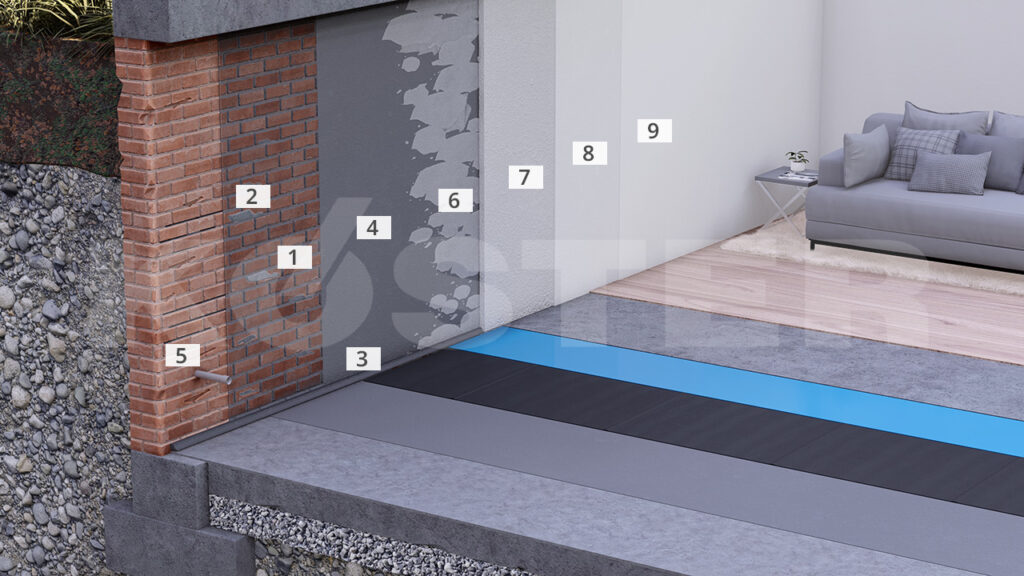

Retroactive waterproofing in existing buildings needs to be done with mineral waterproofing systems. They have excellent bonding characteristics to mineral surfaces and won’t detach from wet and moist substrates.

The material is applied to substrates that have to be sound and solid as well as free from bond inhibiting agents. Older plaster coats have to be removed; the joints raked out and all loose particles removed. As primer, KÖSTER Polysil TG 500 is used. It hardens the substrate as well as reduces the mobility of salts. Masonry repair and the installation of a fillet at the wall-floor junction is done with KÖSTER Repair Mortar Plus.

KÖSTER NB 1 Grey is used as the waterproofing layer. To get a lighter surface finish, use KÖSTER NB 2 White for the final coating.

Pipe penetrations are waterproofed using KÖSTER KB-Flex 200 and sealed with KÖSTER KB-Fix 5.

In the case of damage to basement walls caused by moisture, generally a KÖSTER Restoration Plaster should be applied. KÖSTER Restoration Plasters are specially designed for the restoration of masonry with high salt and moisture contents. KÖSTER Restoration Plasters help to dry out the wall and absorb remaining salts. They don’t contain lime or gypsum, are open to water vapor diffusion and create a healthy and comfortable room climate.

Before the application of the main plaster coat, a plaster key made from KÖSTER Restoration Plaster Key or the chosen KÖSTER Restoration Plaster mixed with KÖSTER SB-Bonding Emulsion is applied to provide a larger surface area and ensure an optimal bond to the substrate. KÖSTER Restoration Plasters are available in different varieties (grey, white, fast and light). KÖSTER Restoration Plaster White is often used in older buildings without subsequent painting. KÖSTER Fine Plaster creates a very smooth surface and can be applied when desired to meet architectural goals. KÖSTER Restoration Plasters can only be painted over with breathable (open to vapor diffusion) paints such as KÖSTER Silicone Paint White or KÖSTER MF1.

Always adhere to the specifications in the respective Technical Guidelines.

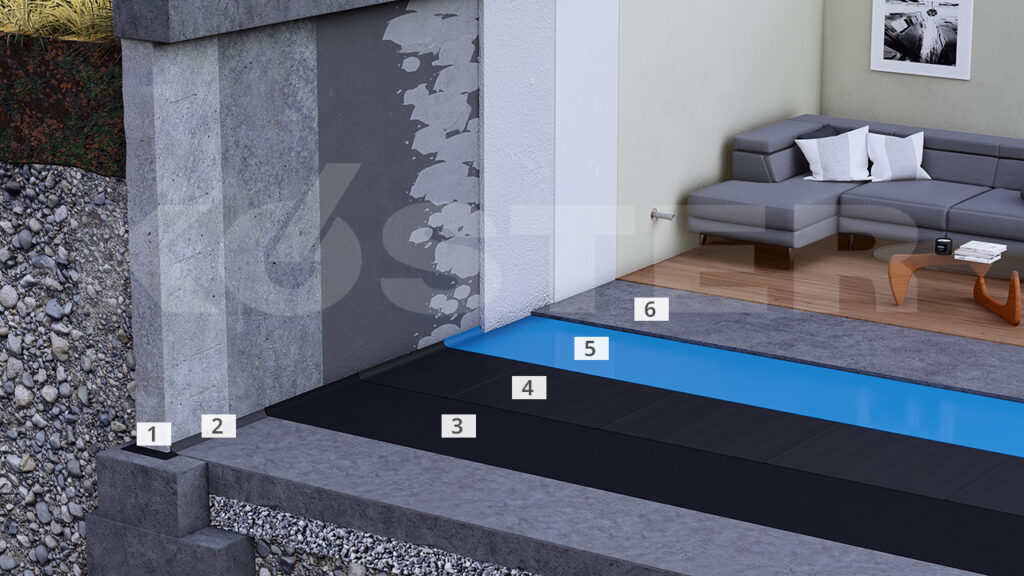

Fast, easy application without long waiting times: Waterproofing of the floor slab with KÖSTER KSK cold applied, self adhesive waterproofing membranes.

To avoid rising moisture, it is necessary to install a horizontal barrier underneath the wall with KÖSTER Fix-Tape 15 SY.

The priming is done with solvent free materials such as KÖSTER KSK Primer BL, KÖSTER KBE Liquid Film, or KÖSTER Bitumen Primer. As a standard the primed surface of the floor slab is waterproofed with the cold applied, self adhesive waterproofing membrane KÖSTER KSK SY 15. Overlap the joints 10 cm. The waterproofing layer is carried up the wall and secured with the KÖSTER Butyl Fix-Tape Fleece

The applied KÖSTER KSK Membranes have to be protected from mechanical damage as work continues. Before pouring the screed or self-leveling underlayment, a gliding layer of customary PE-Foil is applied. KÖSTER SL Premium is ideal for protecting the surface. The system aso needs to be connected to the vertical waterproofing of the adjacent walls.

Always adhere to the specifications in the respective Technical Guidelines.

Mineral waterproofing systems have the advantage of excellent bonding properties of the waterproofing material to mineral substrates, the bond between the individual waterproofing layers is excellent too. The longevity of such systems is ideally the lifetime of the building.

To avoid moisture rising through the wall due to capillary action, it is necessary to install a horizontal barrier beneath the wall made from KÖSTER NB 1 Grey (mixed with KÖSTER NB 1 Flex) or the crack bridging material KÖSTER NB Elastic.

To harden the substrate the bottom slab is primed with KÖSTER Polysil TG 500. At the wall floor junction a fillet made from KÖSTER Repair Mortar plus is installed to prevent stresses in the subsequent waterproofing layers.

The area waterproofing is normally achieved with KÖSTER NB 1 Grey mixed with KÖSTER NB 1 Flex. In case of pressurized water the waterproofing needs to be done with the KÖSTER KD System.

Alternatively the crack bridging waterproofing products KÖSTER NB Elastic Grey or KÖSTER NB 4000 can be used to waterproof the floor slab. KÖSTER SL Premium is ideal for protecting the surface.

Always adhere to the specifications in the respective Technical Guidelines.

All Rights Reserved by Talrak Construction Pvt. Ltd.

Designed & Developed by Contentributor.